What are AGVs

An Automated Guided Vehicle (AGV) is essentially a robot that navigates itself around a warehouse facility with the help of floor markers, wires, magnets, lasers, or computer vision. These highly versatile machines have been around for over 40 years, albeit in its rudimentary form. You would often spot them in manufacturing facilities transporting raw materials, work-in-process, and finished goods. Of late, they have been making themselves useful in warehouses and distribution centers moving materials around the facility.

Why are AGVs reliable?

Technologies that guide AGVs are floor markers, computer vision, etc., the technology is flexible to operate and move across different types of environments. This, in turn, allows operators to change vehicle routes and expand their AGV system according to their needs. As a result, this makes the technology fully scalable, flexible, and capable of adapting to floor layouts and operational changes.

AGVs rely on a central control system (CCS) that allows operators to strictly control their movements and acceleration within the facility with a high level of precision. Most importantly, proximity sensors detect obstacles which allows safe movement across the facility. Additionally, they are capable of stopping when necessary. To achieve this level of freedom of movement, AGVs use radio frequencies to wirelessly communicate with the CCS.

Additionally, operators can direct vehicles precisely to the exact location to pick or drop cargo. Fortunately, GPS systems equipped in AGV’s makes this possible.This GPS capability also provides real-time visibility as to the operations associated with these vehicles and provides insightful and up-to-date data that allows managers to detect inefficiencies and take corrective measures.

The Value of AGVs in a Warehouse Environment

The modern supply chain is witnessing warehouse automation in the form of various autonomous guided vehicles such as automated stackers, forklifts, pallet trucks, and small rack-carrying robots such as Kiva and Fetch.

They leverage machine learning and deep learning to program themselves onto their designated paths and related processes. These vehicles are proving to be the safest alternative to material handling by warehouse clerks (for labour-intensive and repetitive tasks).

There are four key advantages that autonomous vehicles can add to the warehouse:

Safety:

These driverless vehicles are the safest option for material handling. They take up the heavy load of oversized cargo and equipment safeguarding warehouse clerks from lifelong injuries and physical exhaustion. Furthermore, it also prevents expensive material damage. The programming designates safe paths. AGV sensors have the ability to command. Even though, paths are commonly used. They either directly slow down or stop as it senses its proximity to objects or people.

Flexibility:

Overall, most of the autonomous vehicles have an integrated warehouse management system. Automated Storage and Retrieval Systems, conveyors, etc. Also, their mobility prevents them from being a permanent obstacle.

Reduced Costs:

Obviously, machinery do not contain a body clock. Due to this aspect they are curated to work 24/7 on-demand. Reducing significant labour costs, these low maintenance, highly efficient vehicles also provide reliable speed making delivery estimations easy.

Increased Productivity and Precision:

The ability to integrate with automated storage and retrieval systems, warehouse management system, and sensor technology makes these vehicles accurate. They work at a consistent and reliable speed, making material handling time efficient, consistent, and less prone to errors.

The Current State of AGVs

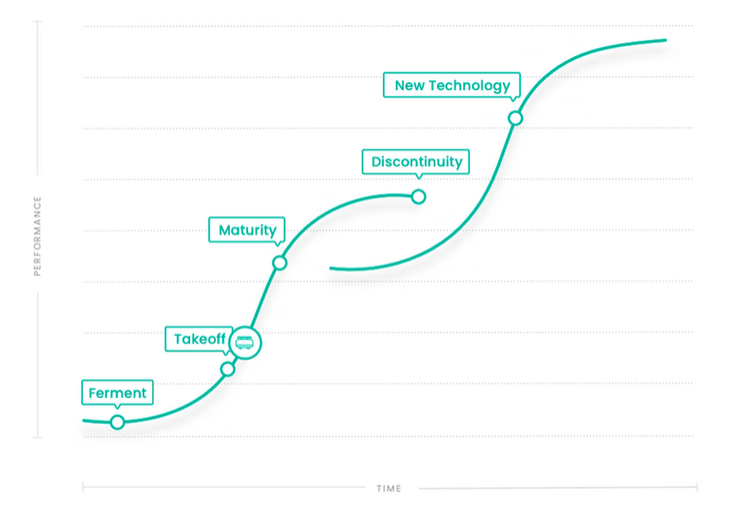

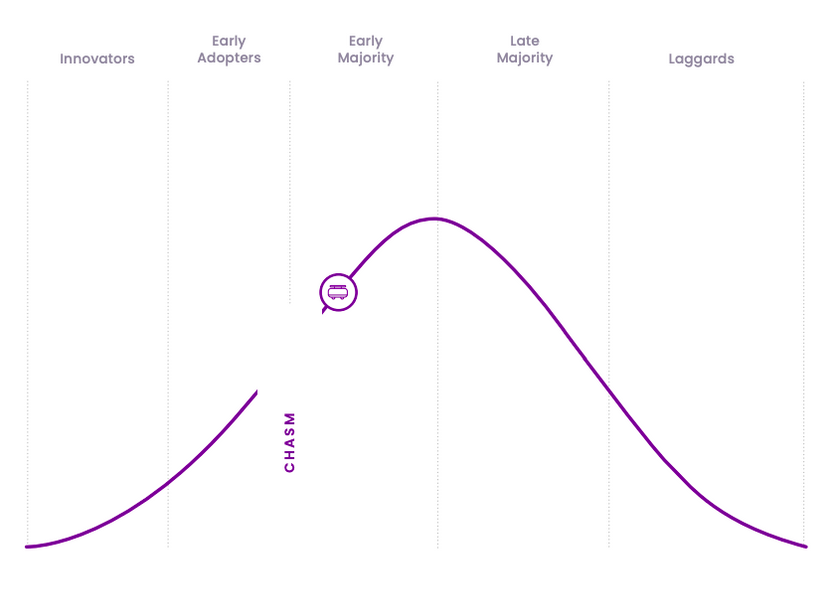

In a nutshell, every automated guided vehicles has a modern automated warehouse process embedded inside.They are becoming integral parts of warehouses and distributions centers today. In relation to the S-Curve, AGVs have recently passed the Takeoff Stage and is on its way to the Maturity Stage. The following point in the curve signifies:

1. Technology recently overcame a significant obstacle

2. Technology has adopted the Early Majority.

In this position, the technology has already crossed the Chasm of Death, which means it is likely that it has the potential to become a key solution to improve efficiency in warehousing operations. In recent years, companies such as Amazon, have adopted AGVs in their distribution centers to gain a competitive advantage. Growth and innovation are consistent, with expectation of more growth for a few years to come.

The Technology Adoption Lifecycle

In regard to the Technology Adoption Life Cycle, AGVs are now seen as being implemented by the Early Majority. Adoption by this group means that thought leaders are increasingly becoming successful in influencing decision makers about the benefits of the technology. It also means that decision makers are starting to see how AGVs can benefit their businesses and are willing to embrace the solution.

To support AGVs’ position in the graph, MHI’s Annual Industry Report 2020 stated that 18% of respondents are using the technology in their operations today. This adoption rate is a significant leap compared to two years ago where it was only implemented by 11% of respondents. Because of this jump in adopters, it has crossed the Chasm of Death and is more likely to be embraced by decision makers in the supply chain industry.

Is it Time for You to Consider AGVs?

In conclusion, we recommend to decision makers, who have the financial capability to accept risk and invest in new technologies, to begin testing and adopting Automated Guided Vehicles. As we have discussed, AGVs have the potential to takeover many repetitive tasks within the warehouse with a high level of consistency and efficiency. Adopting it now will help you gain a competitive advantage in the market, because so far, it has only been implemented by the first Early Majority of adopters.

AGVs’ position in the S-Curve of Innovation and Technology Adoption Life Cycle demonstrated its continuous evolution. Having crossed the Chasm of Death, the technology is seen as becoming a standard solution within the warehouse environment.

If you are stepping up and embracing warehouse digitization, autonomous guided vehicles are a technology that can help you significantly. While the initial investment in autonomous vehicles may be too hefty for small businesses right now, with constant innovation, the cost will become increasingly affordable for even small warehouses and distribution centers.

If you are thinking of investing, it’s a great time to start learning more about it ahead of adopting it in due course of time. Call us now to know more.

Related Articles: