What is Robotics and Automation

Robotics is a branch of engineering and science. It deals with the design, construction and operation aspect of things. Most importantly, use of robots who are programmed to do certain tasks. They can either be autonomous or semi- autonomous which are capable of interacting with the physical world using sensors.

An advantage to using robots is that they don’t suffer from the same limitations as humans. They can perform repeated tasks in a very consistent manner. Which can help reduce costs originated by human inconsistencies and errors. Moreover, hazardous environments endangering human lives uses them. Other human-related limitations robots don’t experience include sickness, sleepiness, hunger, inconsistent performance, and emotions – among others.

A set of operational tasks refers to Automation. Which is performing autonomously with minimal human assistance. This lets humans focus on more complicated and mentally intense tasks that are impossible or hard to replicate using automation. Because, automation is a proven technology that allows businesses to increase efficiency. Several industries, such as manufacturing, transportation, information technology, warehousing, and more use it .

The Value of Robotics and Automation in a Warehouse Environment

Unfortunately, warehouses have repeatable, process-oriented, and error-prone processes. They are tasks such as as receiving, picking and put-away. Robotics and Automation have the ability to take over these repetitive tasks from humans. They can in turn achieve a more consistent and accurate warehouse operation.

Transferring the most repetitive and dull tasks to robots can improve employee engagement and retention rates. This is due to warehouse personnel feeling more fulfilled when tackling more dynamic roles. Likewise, operational analysis, customer service, maintenance, and more.

Another benefit of transferring tasks to robots is the increase in warehouse safety. In 2018, the warehouse and storage subsector recorded 26 fatalities and a 5.1% rate of injury and illness cases. Transferring dangerous tasks, such as the operation of heavy equipment and machineries and working under extreme hot and cold conditions, to robots can help lower the fatality and injury rates and help lessen the impression that the warehouse is a dangerous workplace.

Furthermore, Robotics and Automation can bring substantial benefits in 24/7 warehouse operations. Especially in the age of e-commerce, having an automated warehouse that requires little to no human intervention has the potential to address the need for an always-on warehouse as well as the challenge of low unemployment rates and attracting and retaining employees.

The Current State of Robotics and Automation

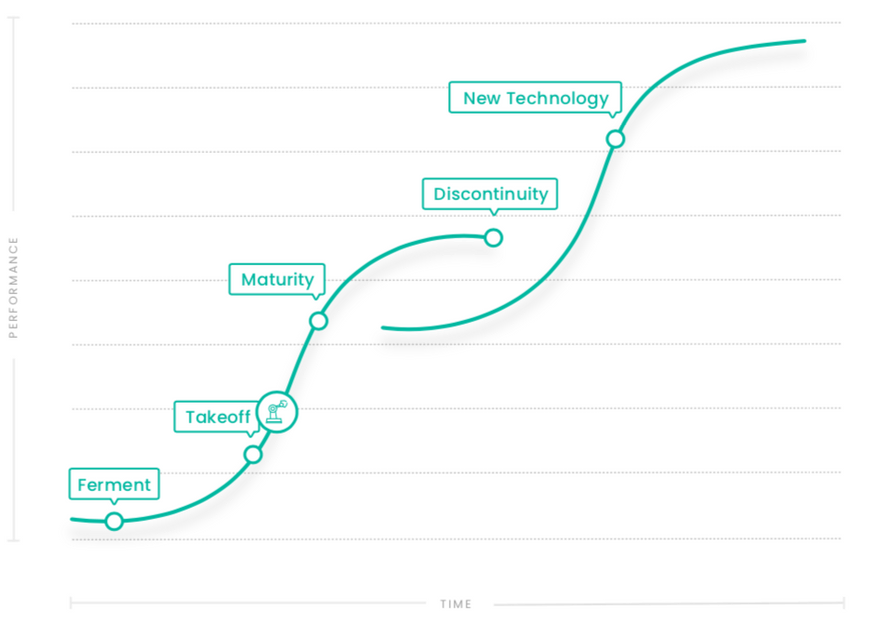

In regard to the S-Curve of Innovation, Robotics and Automation are in between the “Takeoff” and “Maturity” stages. Up to date, technologies overcame the single most obstacle “adoption’. Even though majority of the early adopters implemented it. Moreover, because Robotics and Automation are transitioning to the Maturity stage, the general public will be adopting these technologies soon. Thus, indicating a decline in the risk involved when investing in these technologies.

The position of the technology on the S-Curve is further strengthened by MHI Annual Industry Report 2020, where 67% of the respondents are convinced that Robotics and Automation have the potential to disrupt the industry or create a competitive advantage for their business. We also believe that this will be the case because the technology has gained maturity and there are fundamental and important industry needs creating market demand. Additionally, as the technology continues to mature, we expect cost to decrease and standardization to take place, which will result in greater adoption rates.

Technology Adoption Life Cycle

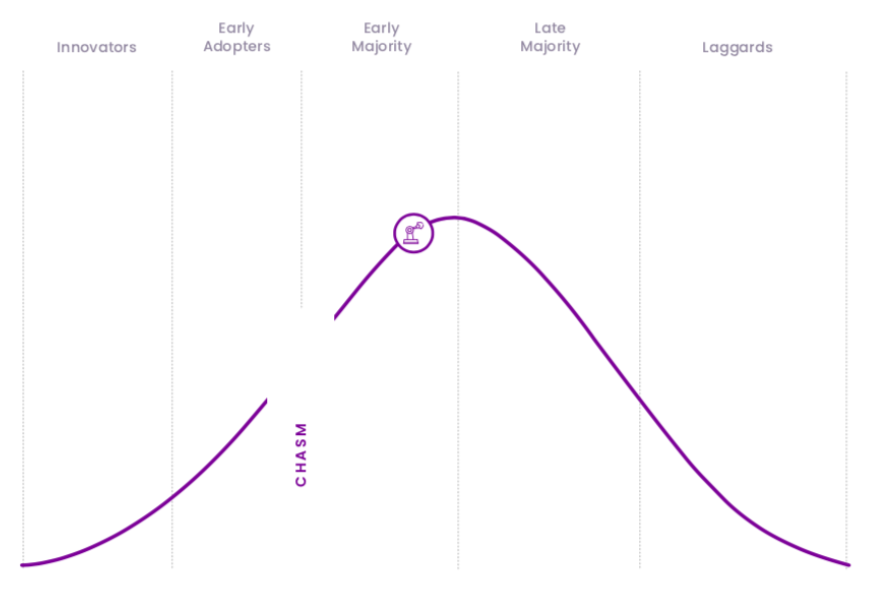

In relation to the Technology Adoption Life Cycle, Robotics and Automation are being adopted by the Early Majority. This indicates that decision makers are seeing the benefits of the two technologies and how they are a fit to their businesses. Furthermore, being adopted by the Early Majority indicates that Robotics and Automation have crossed over the Chasm of Death, which means that they are most likely to become standard technologies in the industry.

To support Robotics’ and Automation’s position in the Technology Adoption Life Cycle, MHI reported that 39% of the respondents in their 2020 Annual Industry Report have adopted both technologies into their businesses. Additionally, it was also reported that more than 58% of respondents will be using these technologies within one to two years.

Best Time to Adopt

Businesses should begin understanding the robotics technology and find a way to fit its application to their operations. The technology may seem unrealistic to a good number of businesses today, however, it is important for businesses to become educated as to where they can potentially fit them in the future. In terms of automation, this is the time to begin adopting them as a way to increase efficiencies in the warehouse and reduce error rates.

It is important not to ignore where each of these technologies sit in relation to the S- Curve of Innovation and Technology Adoption Life Cycle. As we have seen, these technologies have already overcome the most important and significant barriers to market adoption. We can conclude this because it has overpassed the Takeoff stage in the S-Curve of Innovation, crossed the Chasm of Death in the Technology Adoption Life Cycle.

These are clear signals that it’s no longer about “IF” but “WHEN”. So, businesses that look to exploit these disruptive technologies to their advantage must be proactive and ready to adopt. Speak to an expert at TEMPO to help understand these technologies better and know how you can effectively deploy them in your business.

Related Articles: